Das beste Werkzeug für Ihr Handwerk

Die Altendorf Group

Weil bestes Handwerk nur mit bestem Werkzeug möglich ist.

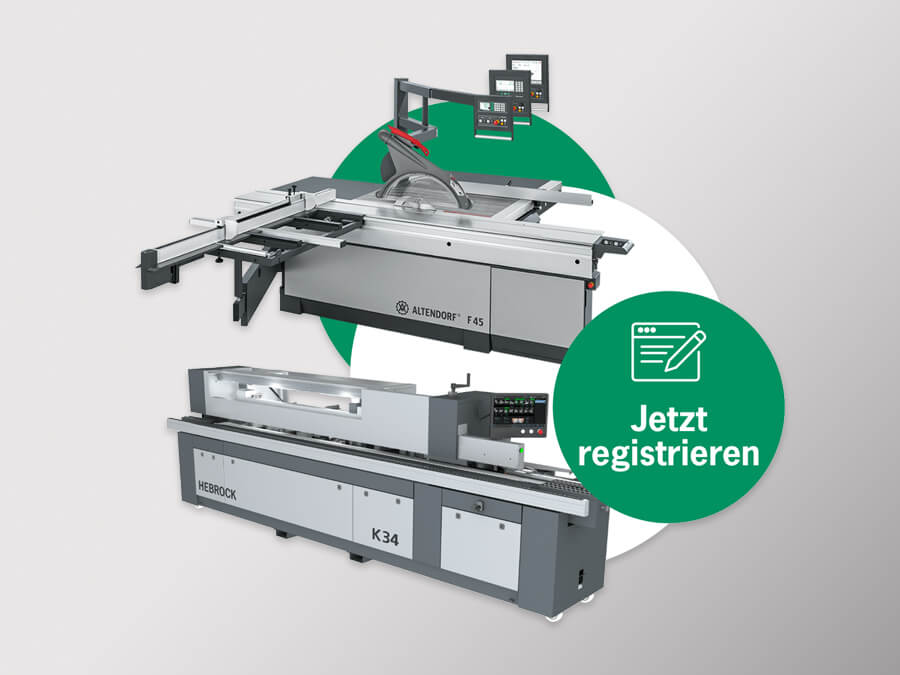

Seit jeher stehen wir für Fortschritt aus Leidenschaft. Und als leistungsstarker Partner des Handwerks führen wir Altendorf Formatkreissägen und Hebrock Kantenanleimmaschinen unter einem Dach zusammen. Wir kennen die Bedürfnisse und Anforderungen der Betriebe genau. Und setzen sie in unseren Maschinen und Service-Leistungen präzise um. Oder anders gesagt:

Wir wissen, was zählt. Ihr Erfolg.

Aktuelles

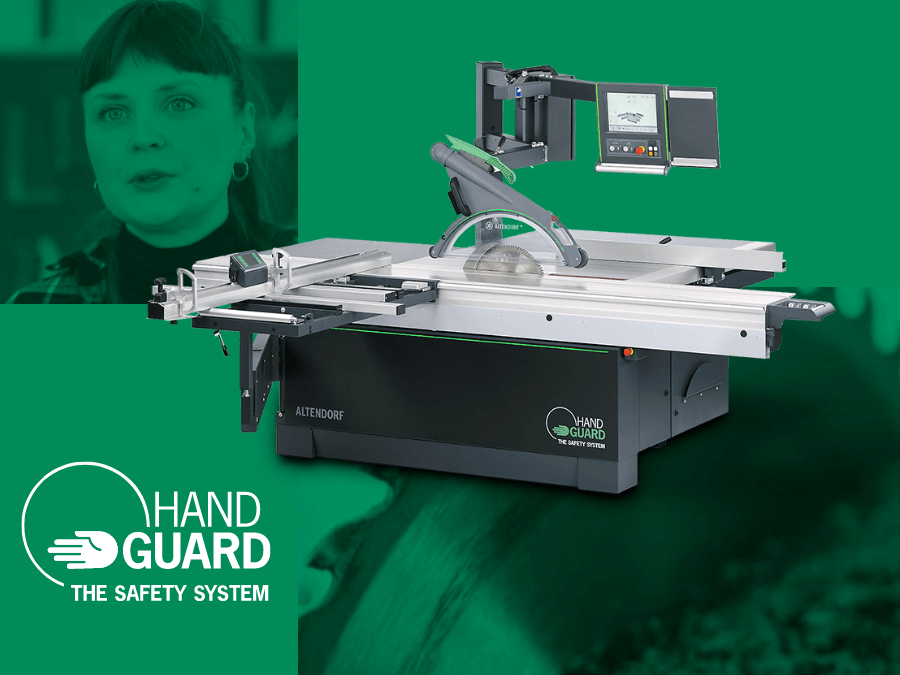

HAND GUARD – nie war Kalkulieren sicherer

Wir wissen, was zählt: die größte Sicherheit für Ihr Handwerk. Und mit HAND GUARD bieten wir seit Oktober 2021 das weltweit einzige optische System für besten Schutz und höchste Produktivität an.

Erfahren Sie mehr über HAND GUARD und sichern Sie sich lukrative Vorbesteller-Vorteile.

Produktvideos

Erleben Sie die Highlights unserer Formatkreissägen und Kantenanleimmaschinen jetzt in unseren neuen Produktvideos.